Casting is an ancient but still important manufacturing process in which molten metal or other materials are injected into molds, which then cool and solidify into specifically shaped components or products. This ancient technique has a rich history dating back thousands of years to ancient civilizations.

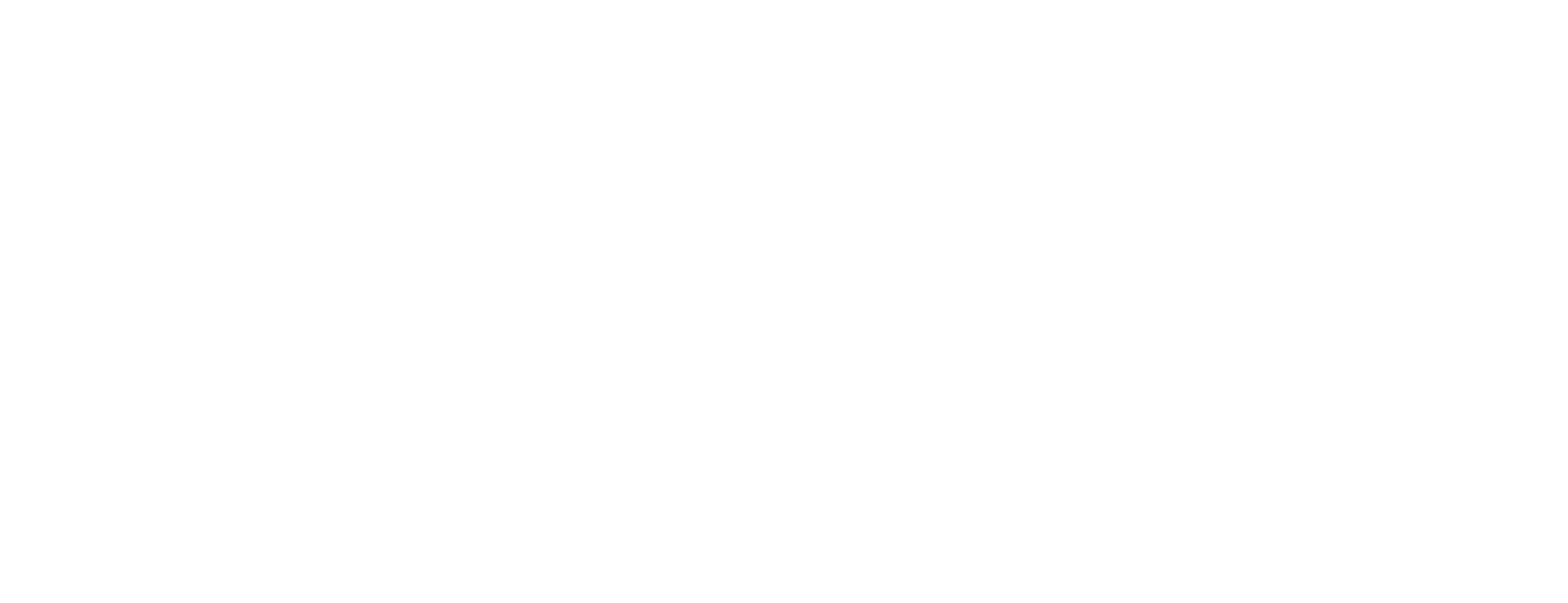

In the course of the evolution of casting, people have developed more and more advanced casting techniques since the Bronze Age. Bronze sculptures from ancient Rome and medieval bell casting are notable examples of the foundry craft. With the beginning of the industrial revolution, casting experienced a significant boom and became an indispensable part of the manufacturing industry. The development of casting not only reflects technical progress, but is also a testament to human ingenuity.

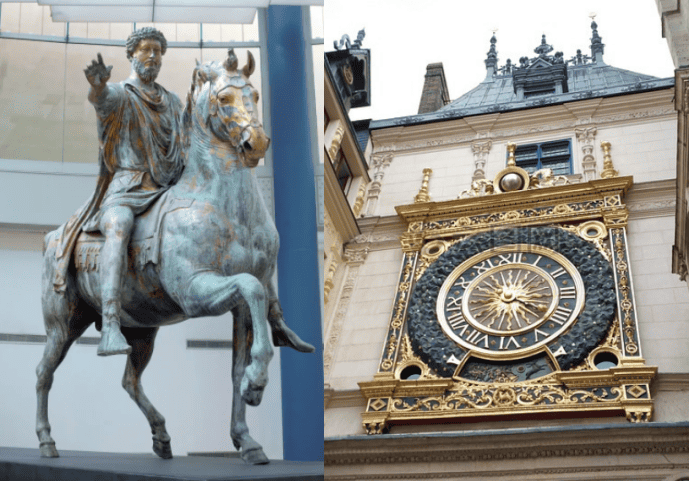

Today, casting is used in almost every industry. From automotive manufacturing to aerospace, from taps to construction and from household appliances to electronic devices, casting provides robust and precise components for these products. Thanks to its flexibility and efficiency, mass production is possible, allowing a variety of products to be brought to market at relatively low cost, enriching people’s lives.

Casting not only creates the basis for the reliability and durability of products, but also increases the efficiency and quality of the manufacturing industry through continuous innovation. Therefore, the importance of casting goes beyond the production process and profoundly influences various aspects of human life and drives innovation and development in various industries.

Casting is an important process for the production of complex components, which includes important steps such as making the mold, melting the material and injecting the mold.

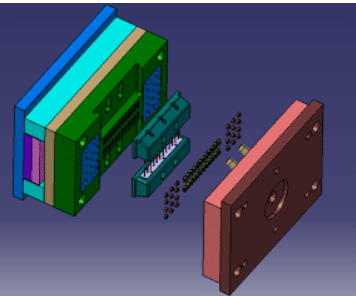

The production of the mold is the first step in the casting process and determines product shape and size of the final product. Depending on the requirements and complexity of the product, the molds can be simple or composite. Precise and durable molds are critical to the success of the casting process and have a direct impact on the quality of the final product.

Secondly, the melting of the material is the most important step in the casting process. Typically, metals or alloys are heated to high temperatures until they reach their melting point. This energy-intensive process transforms the molten material into the prototype of the final product.

The molten material is then injected into the prepared mold. This step often requires precise injection or pouring techniques to ensure complete filling of the mold cavity while preventing the formation of bubbles and other defects. The injection process can vary depending on the casting material and product requirements.

Each step in the casting process plays a crucial role. The precision in making the mold determines the shape of the product, the high-quality molten material ensures product strength and durability of the product, and accurate injection is critical to the details and surface quality of the product. The success of casting depends on the coordination and precise execution of these steps.

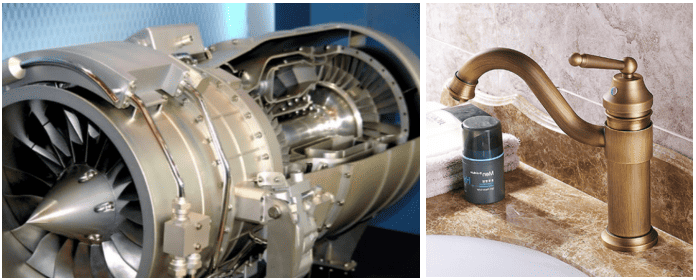

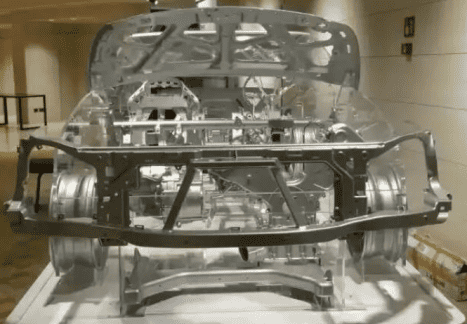

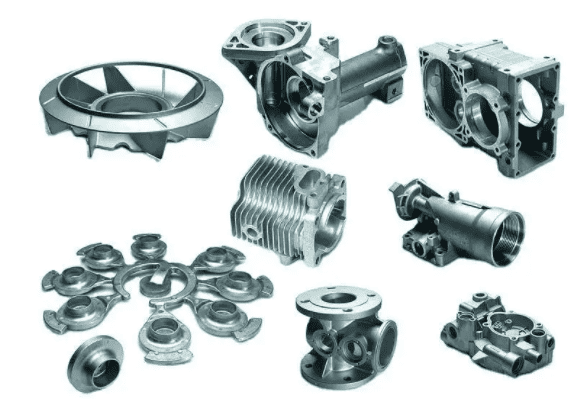

The casting process plays an important role in the production of necessary components and structures in various branches of industry. In the automotive industry, important components such as engines, transmission systems and brake systems are often produced by casting. Casting is an effective means of producing complex shaped components that are both strong and durable.

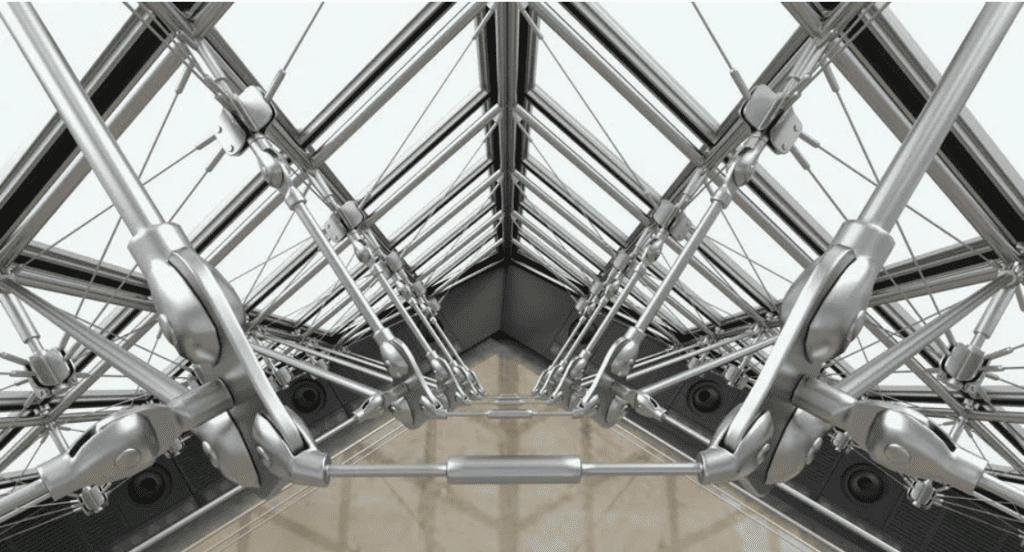

Casting is also widely used in the aerospace industry. Engine components, structural elements for aviation and numerous aerospace equipment components are manufactured using high-precision casting processes. The use of casting in the aerospace industry not only improves the quality of the components, but also reduces the weight of the overall structure, which is crucial for the performance of the aircraft.

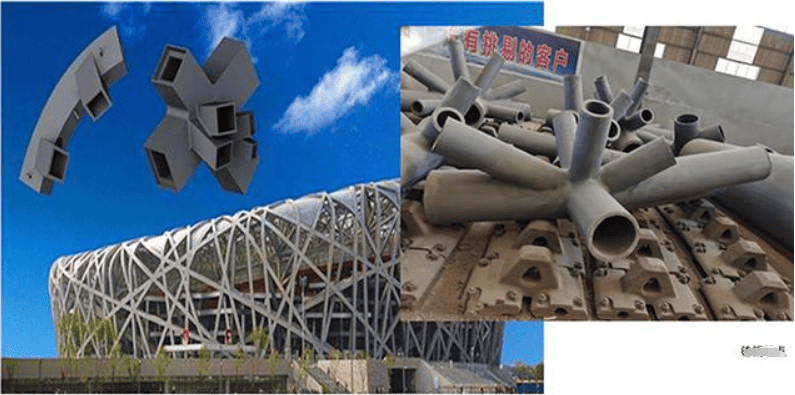

In the construction industry, casting is used to produce a range of supporting and connecting elements in buildings. Large fasteners for steel structures, bridge components and components for architectural decorations can all be produced using the casting process, which ensures their strength and stability.

In addition, casting permeates various aspects of our daily lives. Many components in products such as household appliances, taps and furniture accessories are made by casting, which makes our daily life more convenient while ensuring product quality and durability.

In summary, it can be said that the diverse and widespread applications of the casting process in various fields contribute to the development of modern society in technology and industry.

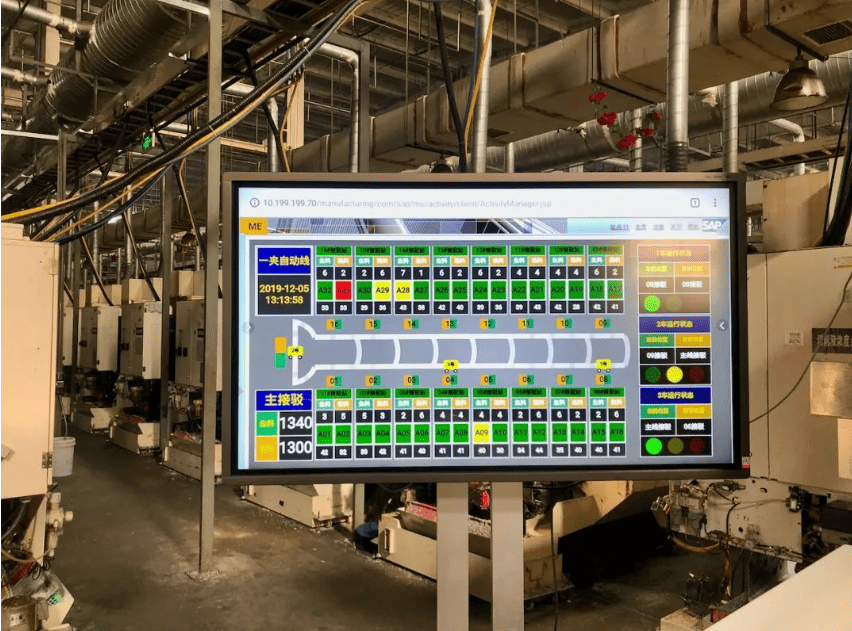

The casting process has undergone numerous technological innovations that are driving progress in manufacturing. Digital casting is a significant technological advancement that optimizes the casting process through advanced mathematical models, simulation techniques and data analysis. This method enables designers to more accurately predict deviations in the casting process and thus optimize product design.

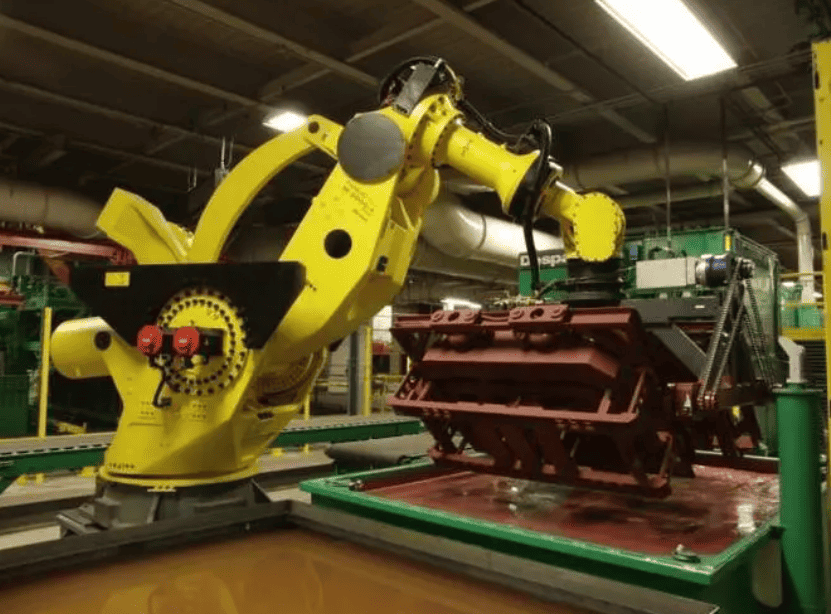

The use of intelligent production technologies is also becoming increasingly important in the foundry industry. By integrating sensors, automatic control systems and big data analysis, smart manufacturing makes the casting process more adaptable and controllable. This application not only improves production efficiency, but also reduces the waste of resources and leads to more sustainable production.

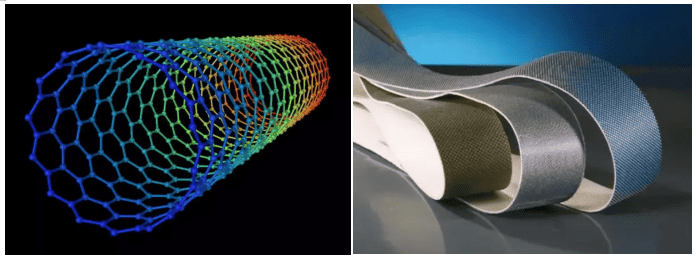

In addition, advances in materials science are opening up new possibilities for casting. The use of novel alloys and composites gives cast products greater strength, corrosion resistance and lower weight, allowing them to be adapted to ever-changing market requirements.

These technological innovations not only make the casting process more efficient and precise, but also offer greater development potential for the processing industry.

The choice of high-quality foundry services is crucial to the success of production and products. Professional foundry services not only offer a high level of technical expertise, but also bring significant benefits in several respects.

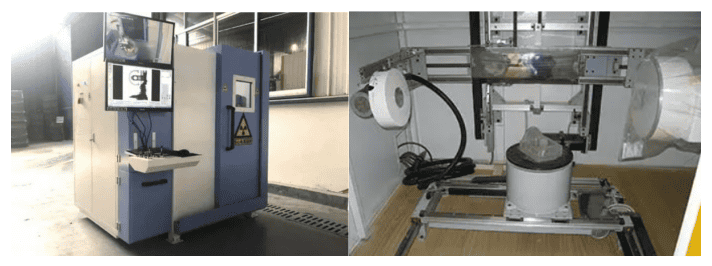

Firstly, quality is the most important criterion when choosing professional foundry services. Through strict quality controls and standardized production processes, they ensure that castings meet or exceed industry standards. This not only affects product performance and durability of the products, but also a company’s competitiveness in the market.

Secondly, professional foundry services focus on precision. High-precision castings are crucial for applications with strict dimensional and shape specifications, such as in the aerospace and automotive industries. Professional service providers use advanced technologies and processes to ensure that the dimensions and shapes of the product meet the design specifications.

Another key factor is reliability. Professional foundry service providers use reliable materials and processes during production to ensure that products are exceptionally reliable and durable during use. This is crucial for critical components and equipment in various industries, as it reduces maintenance costs and improves production efficiency.

In summary, the selection of high quality foundry services is essential to ensure that the end product achieves optimum levels of quality, precision and reliability. This not only helps to meet your requirements, but also improves your company’s competitiveness in a highly competitive industry and ensures that your products stand out.

We pride ourselves on providing professional foundry services to deliver high quality, precise and reliable cast products to our customers. As a leader in the industry, we have advanced technologies and an experienced team capable of meeting a wide variety of industry needs. Whether you need customized components or mass production, we can provide you with flexible and efficient solutions. Explore our foundry services, discover our professional capabilities and our innovative processes. For more information on high quality casting products, please visit our website or contact our professional team.